Brief introduction

Fire resistant oil pollution hazard of EH system:

The quality of fire-resistant oil in steam turbine system of power plant directly affects the safe operation of fire-resistant oil system. The pollution of fire resistant oil causes the corrosion of electro-hydraulic servo valve. Wear of hydraulic servo motor and jamming failure of regulating security parts. In China, there are many abnormal operation of steam turbine and equipment failure caused by anti combustion oil quality problems.

Technical advantages of WSD EHC oil purifier:

1. Balanced charge purification technology: remove pollutants and sludge less than 3 μ M

• Submicron level purification

• Greatly improves the current filtration system

• Remove and prevent sludge and elastic oxide

• Clean the sticking dirt on the valve

• Prevent bearing failure

2.Ion exchange resin: reducing acid value and improving resistivity

• efficient acid scavenger

• does not add moisture to the system

• Improve resistivity

• Anti expansion design core does not burst

• Increase acid absorption capacity

• Long service life of module

• no need for built-in metal core

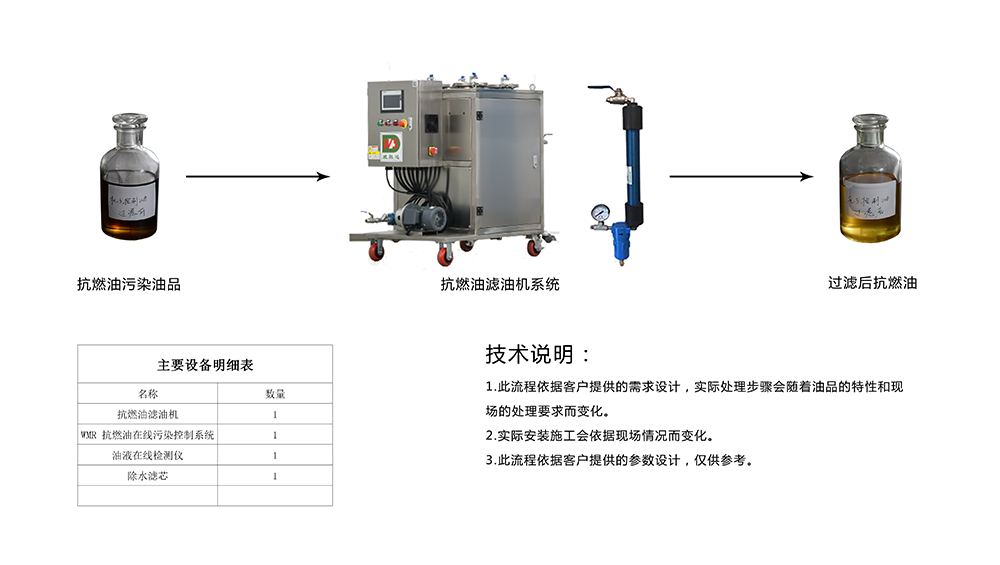

3. Fire resistant oil online water pollution control system

• prevent air pollution from entering the tank

• It can not only remove the water vapor in the top space of the oil tank, but also remove the water in the oil through dry air

• Keep the moisture content of fire-resistant oil tank below 200ppm

• Prevent the formation of acid substances and pollutants in the oil and reduce the replacement of deacidification filter

• The dry air discharged by the system makes the desiccant of the breathing valve continuously regenerate, reducing the maintenance time and labor volume of the breathing valve

• less investment cost and higher return on investment than other technologies

Get a quate

Get a quate

Online consultation

Online consultation