- Home

-

Product

Product Center

Providing suitable models for different fields has been our consistent policy. Therefore, if you need a detailed introduction of the model in your industry, please consult our company's business personnel.

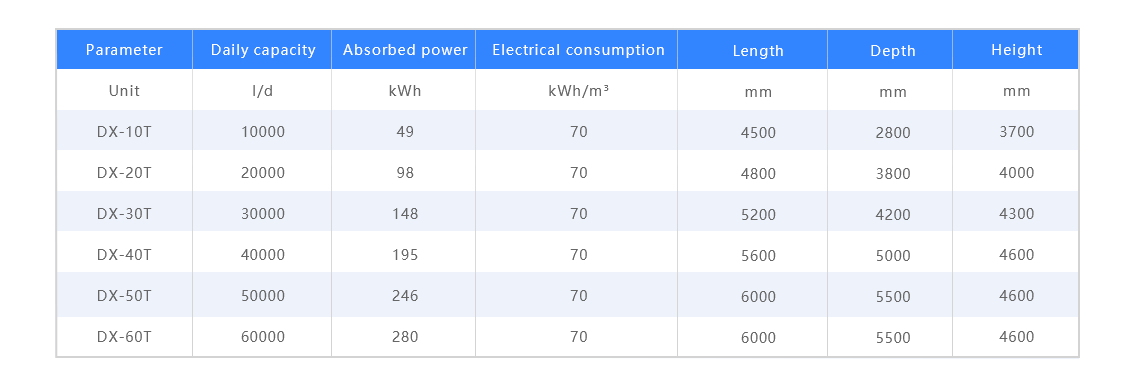

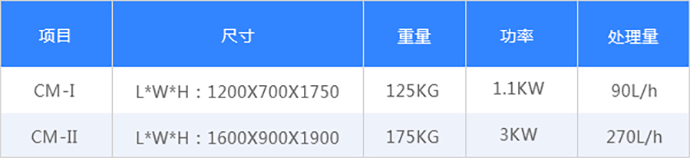

Wastewater treatment equipmentLow temperature vacuum distillation system

Oil purification equipment - Case

- Process

- News

- About

- Contact

Get a quate

Get a quate

Online consultation

Online consultation