Brief introduction

What is varnish:

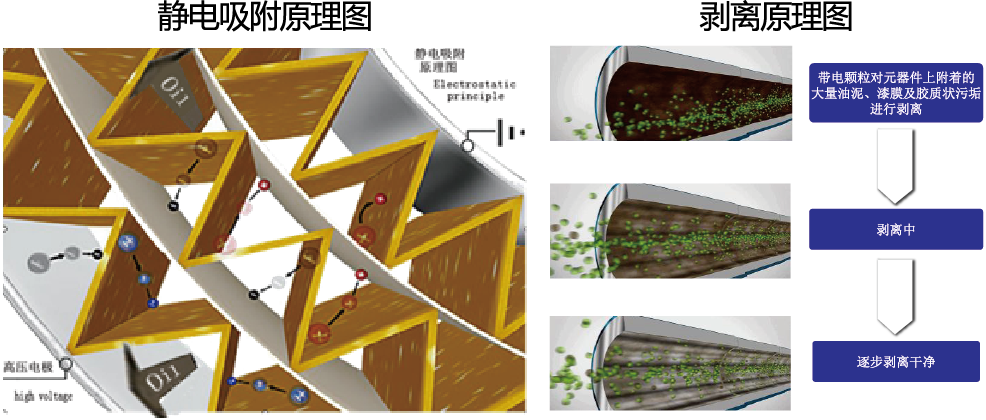

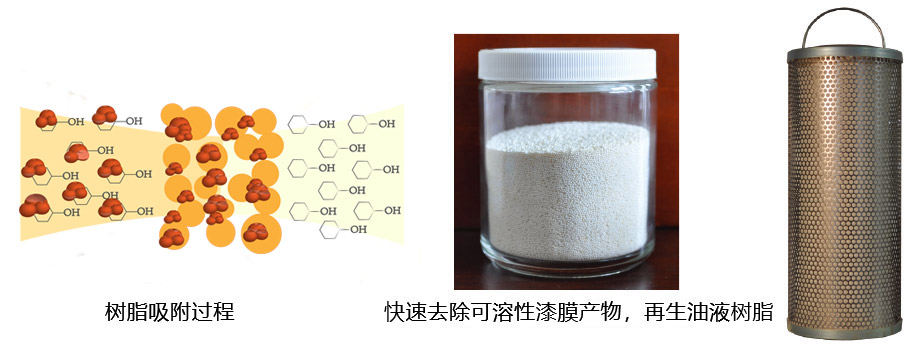

Lubricating oil varnish is a kind of high molecular hydrocarbon polymer, which is the product of oil oxidation. Its color ranges from light brown, brown to tan, which is named for its appearance similar to the film of anticorrosive paint. It is common in the mechanical lubrication and hydraulic system with high temperature, high pressure and high speed rotation. The varnish has polarity and is easy to adhered to the metal surface.

Hazards of varnish:

1. Reduce the clearance between the bearing bush, increase the friction between the surface of the bearing bush and the shaft, and increase the temperature of the bearing bush.

2. For some turbine control oil systems, when the varnish is serious, it can cause the filter screen of the electro-hydraulic converter in the control oil circuit and valves blocked.

3. Clogging filter results in poor lubrication of the equipment.

4. The varnish deposited on the cooler causes poor heat dissipation, oil temperature rise and oil oxidation acceleration.

5. The varnish will adhere to solid particles, which will cause abrasion of equipment.

Get a quate

Get a quate

Online consultation

Online consultation