Working principle

Balanced Charge Sub-micron Purification

WJLTM technology is able to effectively remove all insoluble contaminations, including sub-micron sludge and jellies through the agglomeration of charged particles. WJLTM can also absorb and clean the reservoir, valves and pipeline via the flow of charged particles, keeping the EHC system clean.

Passing contaminations fluid over a series of electrodes that carefully charge particles, both positive (+) and negative (-), then positively and negatively ionized contaminant particles are attracted to each other, growing in size as they agglomerate. The smaller particles, too small to be caught, are easy to be captured by the filters.

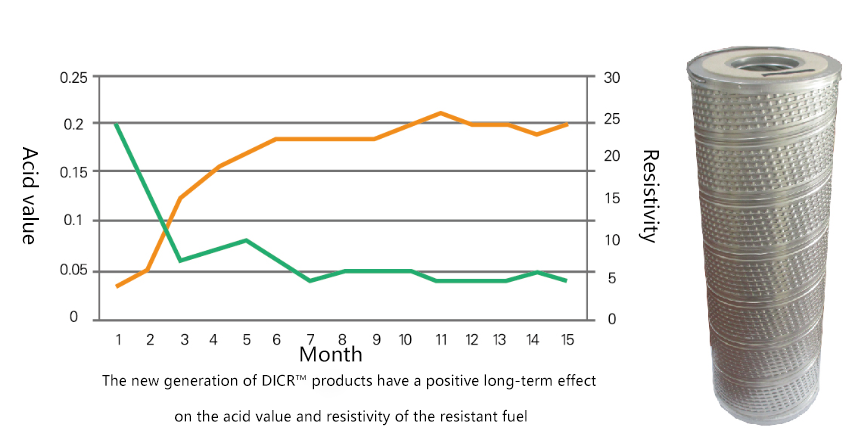

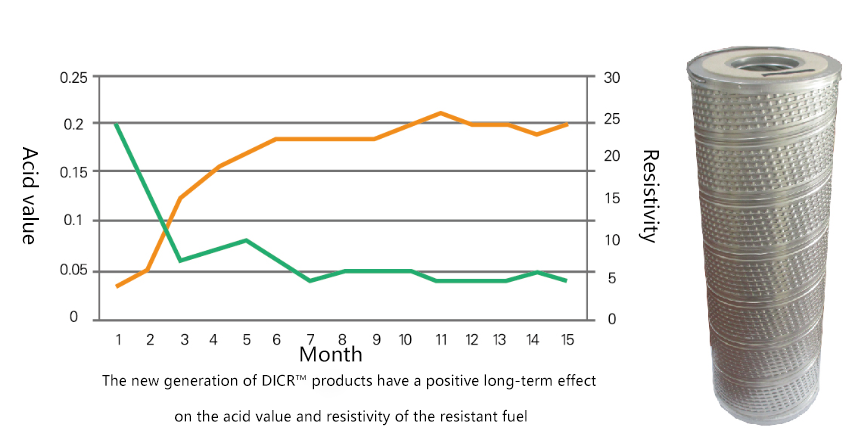

Dry Ion Charged Resin

DICRTM is capable of removing soluble contaminants from acids to metal salts without producing dangerous sub-micron particles. Compared with the other deacidification technology, DICRTM has much higher deacidification ability, long service life, and more efficiency, and our DICRTM technology has a record of more than 20 million hours of successful operation.

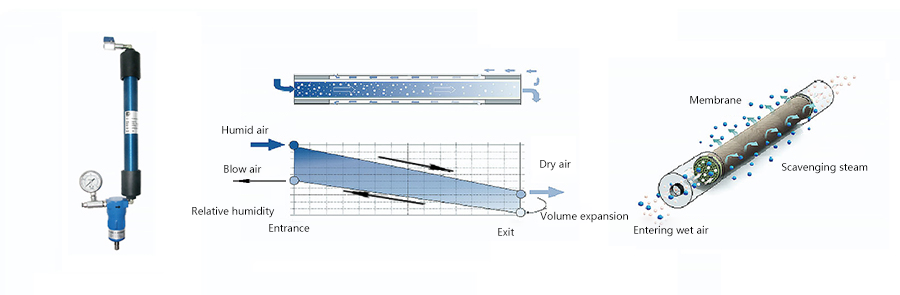

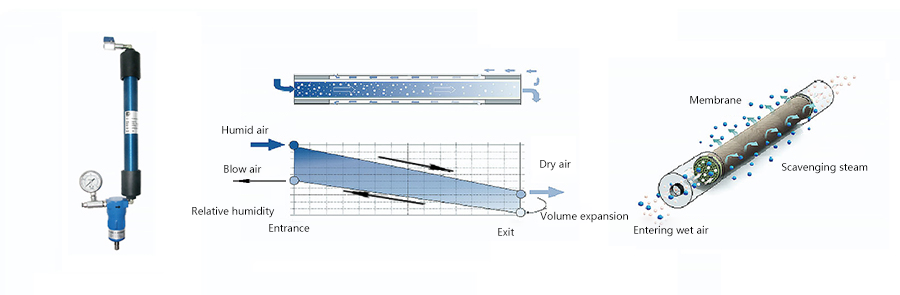

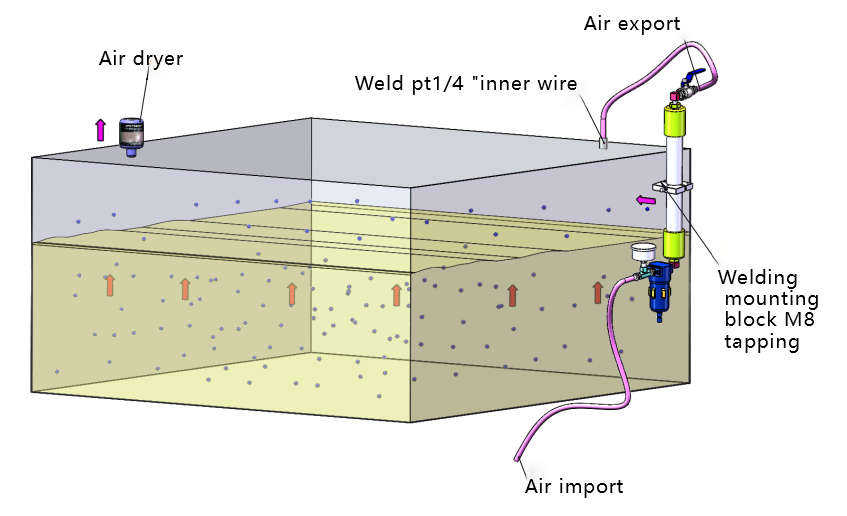

WSD WMRTM- EHC Online Water Pollution Control System

WSD WMRTM blankets your reservoir headspace with super-dry, clean air, fundamentally excluding moisture and contaminants from EHC oil. A low pressure air purge in the headspace accomplishes two important tasks simultaneously: It extracts moisture from the fluid while excluding other contaminants from getting in the system. The result is exceptionally clean, dry oil.

The WMRTM is designed for ease of use. It is manufactured using an advanced hollow-fiber membrane media and an aluminum outer shell. This patented process flows air through the length of the membrane module, where the membrane allows moisture molecules to pass through. The dehydration air is then discharged from the unit at line pressure port. The WMRTM has a -40℃ dew point, which is extremely important for water removal from EHC fluids.

Get a quate

Get a quate

Online consultation

Online consultation