Customer pain points

During the overhaul, it was found that the paint film of the thrust bearing bush was serious, and the temperature of the thrust bearing of the ethylene and propylene Mitsubishi compressor unit was on the high side (the maximum temperature was 106 ℃).

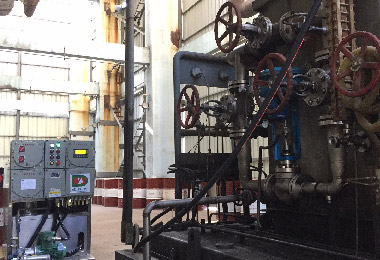

Device name: ethylene refrigerant compressor

Solution: remove paint film

Fluid details

Oil tank capacity: 20m ³

Oil model: turbine oil

Service life of oil: 3 years

Select our scheme

Oil purifier model: WVD-II oil purifier for removing paint film

Operation time of oil purifier: October 2016 to present

Before purification

Paint film tendency index MPC: 5.9

Unit operation: 11C3801 thrust bearing temperature rises to 106 ℃

After purification

Paint film tendency index MPC: 1.2

Unit operation: since October 17, 2016, the paint film cleaning oil purifier has been running on the shared lubricating oil tanks of 11C3801/11CST3901 and 11C3501/11CST3601, and has been running for 37 days until November 23; The temperature gradually decreased from the original maximum 106 ℃ to 90 ℃, the temperature of 11CST3901 thrust bearing synchronously decreased by 6-7 ℃, and the temperature of 11CST3601 thrust bearing synchronously decreased by 5-6 ℃. The three temperature sensors showed that the temperature decreased synchronously, indicating that the effect of removing paint film oil purifier was significant.

Online consultation

Online consultation