Product feature

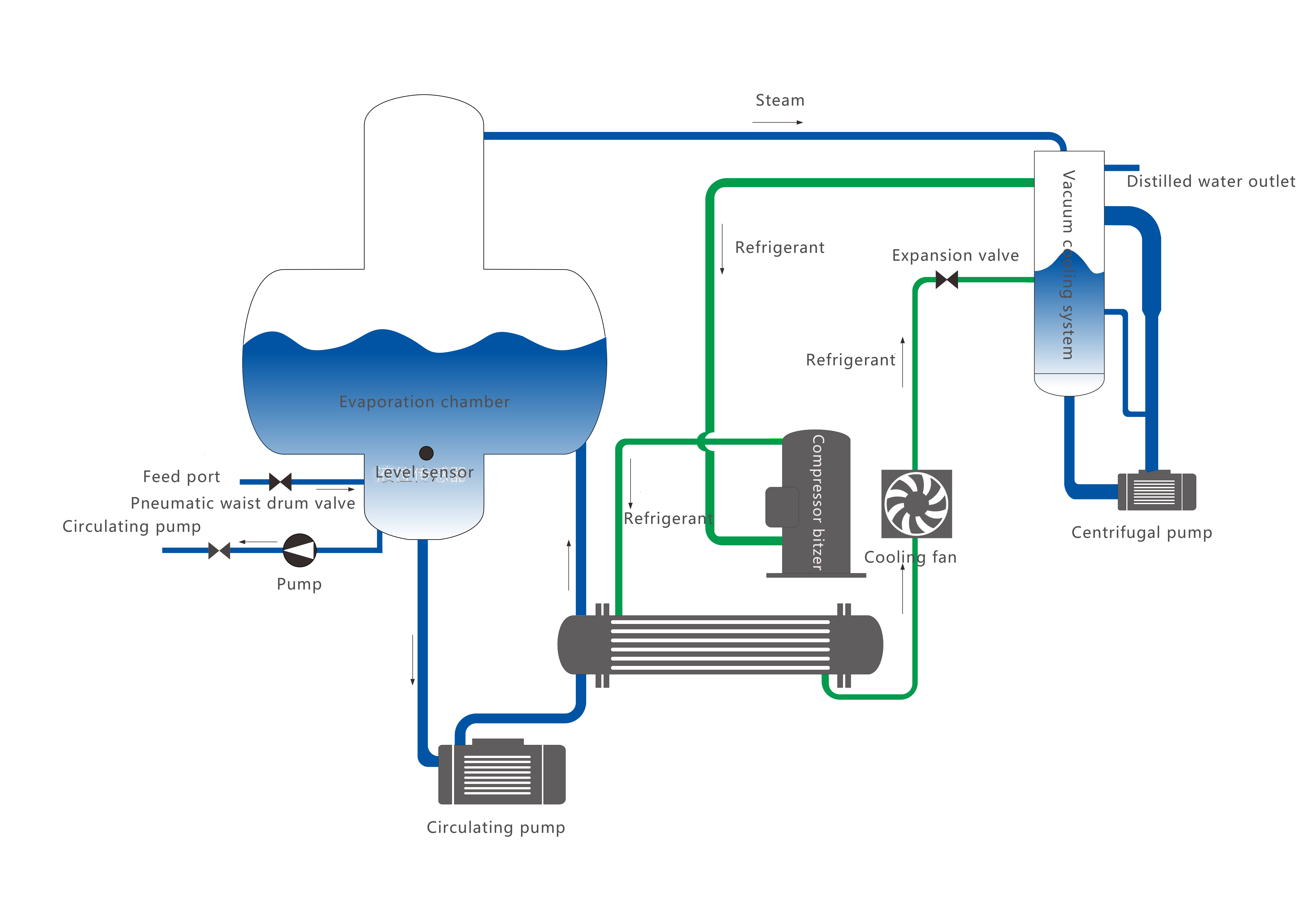

1.Evaporator manufactured in SS AISI 316L.

2.Toroidal coil heat exchanger, manufactured in A-316L (for condensation).

3.Main compressor for heating and cooling the refrigerant (Freon gas R407c or R134a).

4.Control panel with a display to show all operation data.

5.Automatic system to control and dosing the anti-foam agent.

6.Electricity input 380V, III,50Hz.

7.Immersed heat exchanger (for evaporation).

8.SIMENS PLC and screen HMI.

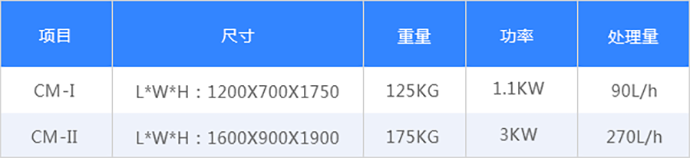

9.Worked with CM/activated carbon system.

10.The parts in contact with the liquid, in special corrosion resistant material (SAF 2507 or TITANIUM) (effluent with a high content of chlorides or fluorides, etc.).

11.Special LT DPC model for highly corrosive fluids, in PVDF lined vessel and graphite or Hastelloy heat exchanger (special for chromic acid).

12.Remote control regulator can realize Internet of things, mobile phone visualization and alarm functions

Get a quate

Get a quate

Online consultation

Online consultation